News

Rolling Stock Modernization – Efficiency, Safety and Extended Service Life

Rolling Stock Modernization offers Efficiency, Safety and Extended Service Life for Rail Equipment

Rolling stock modernization is a cost-effective way to extend the service life of equipment, improve operational reliability and efficiency, and meet today’s safety and performance requirements as well as extend service life of rail equipment. By modernizing, operators can make full use of existing assets while reducing the need for major investments in entirely new equipment.

Why Modernize?

Modernization means upgrading existing equipment with new technologies, components, and software. Future maintenance and service reliability can be ensured when rolling stock is equipped with updated components and compatible software, whose availability can be secured in advance.

As technology, suppliers, and delivery processes evolve, some components may change, have extended lead times, or even become obsolete. Without modernization, this can compromise maintenance capability and create risks of operational delays. Updating the equipment mitigates these risks.

Typical modernization measures include:

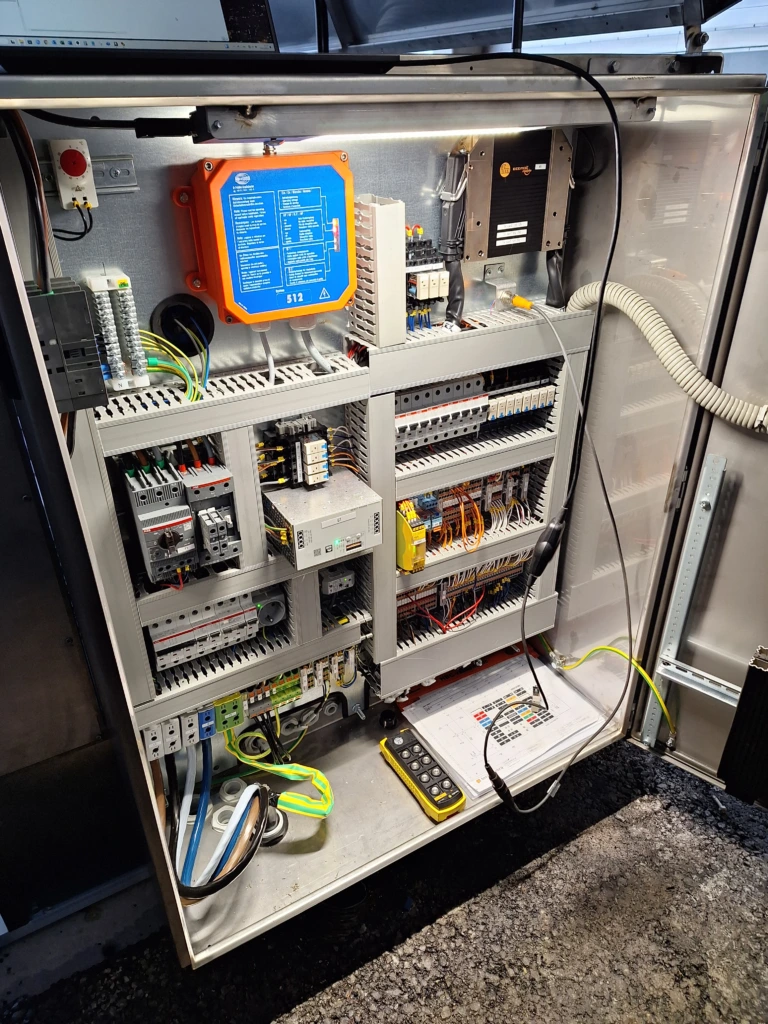

- Replacing outdated control systems with modern PLC (Programmable Logic Controller) solutions

- Adding automation and remote monitoring capabilities

- Replacing mechanical components with more energy-efficient and durable solutions

- Upgrading safety equipment to meet current standards

- Implementing software updates to improve accuracy and usability

Each modernization project is tailored according to the manufacturing year, components used, and specific requirements of the customer.

Benefits of Modernization for Rolling Stock

Upgrading rolling stock provides multiple benefits for operators. While maintenance and annual inspections are part of daily operations, proactive modernization helps avoid peak-season workshop bottlenecks and reduces service delays caused by limited spare part availability.

Key benefits include:

- Improved efficiency and productivity – faster, more reliable operation with reduced downtime

- Enhanced safety – up-to-date safety systems

- Cost savings – reduced maintenance and operating costs

- Adaptability for future needs – longer equipment lifecycle

- Environmental benefits – improved energy efficiency and reduced emissions

Example: OTSO Winch Wagon Mover Modernization

The Saalasti Rails OTSO Winch is a trusted wagon mover used by many customers for shunting operations at loading and unloading areas in rail yards. Some OTSO Winch units currently in operation were delivered as far back as the 1990s. For long-serving equipment, the availability of components and spare parts has decreased over time, making modernization an important consideration.

Modernization benefits for OTSO Winch users:

- Future spare part availability – compatibility with modern components

- Reduced waiting times – scheduled modernization reduces the impact of long spare part lead times, which can be 12 months or more

- Safer and more precise operation – modern control and safety systems

- Extended service life and lower maintenance costs – fewer unexpected downtime events and improved yard operational reliability

Modernization ensures that the OTSO Winch remains a long-term, competitive solution that supports efficient and safe rail yard operations for years to come.

Interested in modernizing your rolling stock?

Contact Saalasti Rails’ experts to explore how modernization can improve the efficiency and reliability of your rail yard operations. Our experienced staff will help you to find the best possible solutions for your rail equipment.